应急安全是大事| 大鹏新区应急基地揭牌及应急产品展示活动

2024-12-11 16:16:51

惯性测量技术,为地下管道打造数字盾牌

2024-11-26 17:57:47

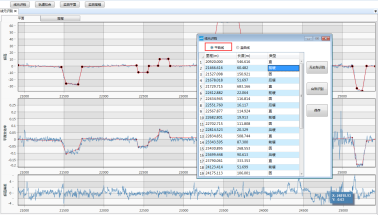

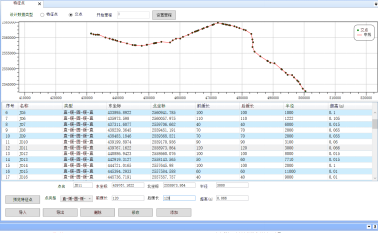

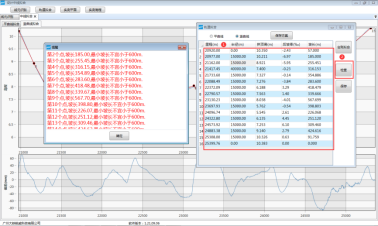

“北斗+惯导”普速铁路轨道线型测量技术分析(二)

2024-12-20 16:30:42

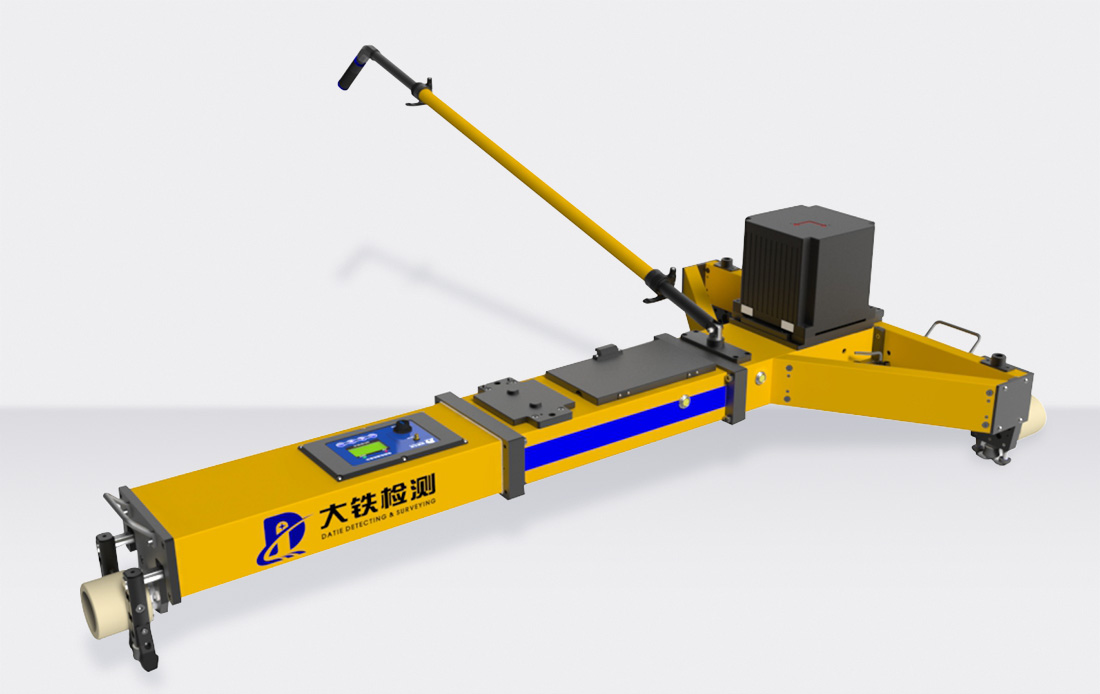

惯导轨道测量仪无砟轨道抬升纠偏整治工程应用

2025-01-06 10:36:03

普速铁路精测精捣作业里程系统如何统一?

2025-02-11 09:13:03

马来西亚Tawau:管道惯性测量仪助力非开挖电力管道探测

2025-02-13 17:22:13

什么是惯导管道三维测量仪?

2025-02-18 17:59:07

静力水准仪:复杂施工环境中的安全屏障

2025-02-26 15:38:58

管廊自动化沉降监测设备安装实践分享

2025-03-17 21:22:29